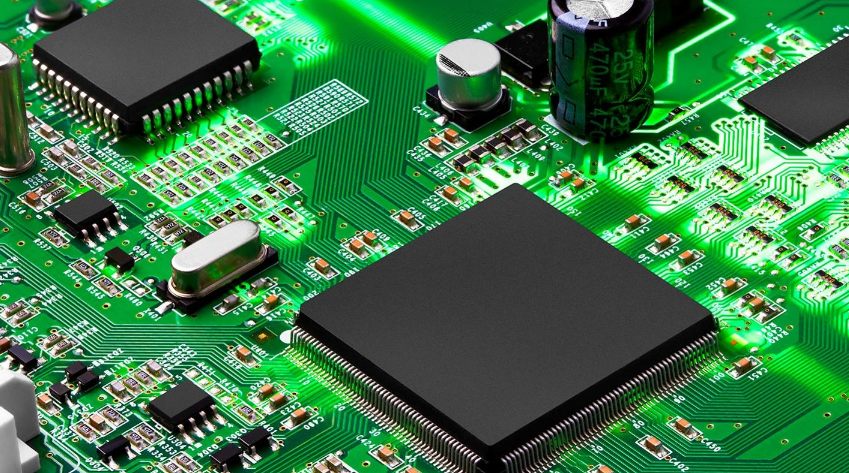

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a platform to connect and support various electronic components. Whether it’s in your smartphone, computer, or home appliances, PCBs are integral to the functioning of almost all electronic devices. But have you ever wondered how these intricate boards are made? The process of PCB fabrication is both an art and a science, requiring precision and expertise to bring a design from concept to reality.

Global Well as a professional PCBA manufacturer vendor, focuses on the production and manufacture of precision multilayer boards and special boards and has set up branches in many cities. The company adheres to the core values of “Customer First, Quality First, Continuous Innovation, Win-Win Cooperation” and is committed to providing global customers with good prices, good quality, good service, and fast delivery, creating greater value for customers and employees.

Understanding the Basics of PCB

What is a Printed Circuit Board?

A Printed Circuit Board (PCB) is a flat, insulated board that electrically connects electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. These boards are essential for the proper functioning of electronic devices, providing both a mechanical and electrical foundation.

Types of PCBs

PCBs come in various types, each designed for specific applications:

- Single-Sided PCBs: These are the simplest type of PCBs, with one layer of conductive material and components mounted on one side.

- Double-Sided PCBs: These boards have conductive material on both sides, allowing for more complex circuit designs.

- Multilayer PCBs: Featuring multiple layers of conductive material separated by insulation, these boards are used in more advanced applications requiring higher density and complexity.

Materials Used in PCBs

The materials used in PCBs are crucial to their performance:

- Substrates: The substrate is the base material of the PCB, typically made of fiberglass-reinforced epoxy resin (FR4). This material provides insulation and mechanical support.

- Conductive Layers: Copper is the most common material used for conductive layers due to its excellent electrical conductivity and relatively low cost.

Designing a PCB

Schematic Design

The design process begins with creating a schematic, which is essentially a blueprint for the PCB. The schematic outlines how the various components will be connected electrically. Engineers use specialized software tools to draw and simulate the circuit.

PCB Layout

Once the schematic is complete, the next step is to create the PCB layout. This involves placing the components on the board and routing the connections between them. The layout is a critical step, as it determines the physical arrangement of the circuit and impacts the board’s performance.

Design Software Tools

Several software tools are available to assist in PCB design, including popular options like Altium Designer, Eagle, and KiCad. These tools allow engineers to design both the schematic and the layout, perform simulations, and generate the files needed for fabrication.

Considerations in PCB Design

Designing a PCB requires careful consideration of various factors:

- Signal Integrity: Ensuring that signals are transmitted without distortion or interference is crucial, especially in high-speed circuits.

- Thermal Management: Proper heat dissipation is essential to prevent overheating and ensure the longevity of the components.

The PCB Fabrication Process

Step 1: Design Transfer

The first step in PCB fabrication is transferring the design to the manufacturer. This is done by converting the design into Gerber files, which are the standard file format used to describe the PCB’s layers. These files contain detailed information about the copper traces, drilling, and other features of the PCB.

Step 2: Printing the Circuit Pattern

Once the design files are ready, the next step is to print the circuit pattern onto the substrate. This process involves applying a layer of photoresist, a light-sensitive material, onto the copper-clad board. The board is then exposed to UV light through a mask that defines the circuit pattern. The areas exposed to light harden, while the unexposed areas remain soft and are later removed during development.

Step 3: Etching

Etching is the process of removing excess copper from the board, leaving only the desired circuit pattern. The board is immersed in a chemical solution that dissolves the unprotected copper, revealing the conductive traces that form the circuit.

Step 4: Drilling

Drilling is required to create holes for vias (connections between layers) and component leads. Precision drilling machines, often equipped with laser guidance, are used to ensure accuracy and consistency.

Step 5: Plating

After drilling, the holes need to be plated with copper to create electrical connections between the different layers of the PCB. This process is known as Plating Through Holes (PTH). The entire board is also typically plated to protect the copper traces and improve solderability.

Step 6: Solder Mask Application

A solder mask is applied to the board to prevent solder from bridging between conductive traces and causing short circuits. The solder mask also provides protection against environmental factors such as moisture and contaminants.

Step 7: Silkscreen Application

The silkscreen layer is used to print labels, component designators, logos, and other markings on the PCB. This step is important for assembly and troubleshooting, as it helps identify components and their orientation on the board.

Step 8: Surface Finish

The surface finish is applied to the exposed copper areas to protect them from oxidation and ensure good solderability. Common surface finishes include Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservative (OSP).

Step 9: Electrical Testing

The final step in PCB fabrication is electrical testing to ensure that the board functions as intended. This involves checking for shorts, opens, and other defects using methods such as Flying Probe Testing or Bed of Nails Testing.

Advanced PCB Fabrication Techniques

High-Density Interconnect (HDI) PCBs

HDI PCBs are designed with finer lines and spaces, smaller vias, and higher connection pad density than standard PCBs. This allows for more components to be packed into a smaller area, making HDI technology ideal for smartphones, tablets, and other compact devices.

Flexible and Rigid-Flex PCBs

Flexible PCBs are made from flexible materials, allowing the board to bend and flex. Rigid-flex PCBs combine rigid and flexible layers, offering the advantages of both. These types of PCBs are used in applications where space and weight are critical, such as in aerospace and medical devices.

Embedded Components

In advanced PCB fabrication, components such as resistors, capacitors, and even integrated circuits can be embedded directly into the board’s layers. This reduces the overall size of the PCB and enhances performance by minimizing signal paths.

Microvias and Laser Drilling

Microvias are small vias used in HDI PCBs to connect layers. These are often created using laser drilling, a technique that allows for precision drilling of very small holes, enabling the creation of high-density circuits.

Quality Control in PCB Fabrication

Importance of Quality Control

Quality control is vital in PCB fabrication to ensure that the final product meets all specifications and functions correctly. Even minor defects can lead to failures in electronic devices, so rigorous inspection and testing are necessary.

Common Defects and How to Avoid Them

Common PCB defects include solder bridges, broken traces, and misaligned layers. These issues can often be avoided by careful design, proper material selection, and precise manufacturing processes.

Inspection Methods

Automated Optical Inspection (AOI) and X-ray inspection are commonly used to detect defects in PCBs. AOI uses cameras to scan the board for defects, while X-ray inspection allows for the examination of internal layers and solder joints.

Cost Factors in PCB Fabrication

Materials Costs

The choice of materials significantly impacts the cost of PCB fabrication. Higher-quality materials generally lead to better performance but also increase costs. For example, boards requiring high thermal conductivity might use specialized substrates that are more expensive than standard FR4.

Complexity of Design

The complexity of the PCB design also plays a significant role in determining cost. Multilayer PCBs, HDI designs, and boards with embedded components are more expensive to manufacture due to the additional processes involved.

Volume of Production

Economies of scale apply to PCB fabrication as well. Larger production volumes typically result in lower per-unit costs, making high-volume manufacturing more cost-effective.

Lead Time and Its Impact on Cost

The lead time, or the time required to produce the PCB, can also influence cost. Rush orders with shorter lead times often come with a premium price due to the expedited processes required.

Environmental Considerations in PCB Fabrication

Waste Management and Recycling

PCB fabrication generates waste materials, including chemical byproducts and scrap boards. Proper waste management practices, including recycling of materials, are essential to minimize environmental impact.

Hazardous Materials and Their Disposal

Some materials used in PCB fabrication, such as lead and certain chemicals, are hazardous. Safe disposal and handling of these materials are critical to protecting both the environment and human health.

Green Manufacturing Practices

As environmental awareness grows, many manufacturers are adopting green practices, such as using lead-free solder and implementing energy-efficient processes. These practices not only reduce environmental impact but also comply with regulatory requirements.

Future Trends in PCB Fabrication

Miniaturization and Increased Density

The trend towards smaller, more powerful devices is driving the need for miniaturized PCBs with higher component density. Advances in materials and manufacturing techniques are enabling the production of increasingly compact and efficient PCBs.

The Role of AI in PCB Design and Fabrication

Artificial Intelligence (AI) is playing an increasingly important role in PCB design and fabrication. AI algorithms can optimize PCB layouts, predict potential issues, and even assist in automating the manufacturing process.

Innovations in Materials and Processes

New materials, such as advanced polymers and ceramics, are being developed to improve PCB performance in extreme environments. Additionally, innovations in processes, such as additive manufacturing (3D printing), are opening up new possibilities for PCB design and fabrication.

Conclusion

Printed Circuit Board fabrication is a complex and evolving field, integral to the development of modern electronics. From the basic design principles to advanced manufacturing techniques, understanding PCB fabrication provides insight into the technology that powers our world. As we look to the future, the continued innovation in PCB technology will undoubtedly play a crucial role in shaping the next generation of electronic devices.

Frequently Asked Questions

What is the most common material used in PCBs?

The most common material used in PCBs is FR4, a fiberglass-reinforced epoxy resin that provides excellent insulation and mechanical support.

How long does it typically take to fabricate a PCB?

The fabrication time for a PCB can vary, but it typically takes anywhere from a few days to a few weeks, depending on the complexity of the design and the production volume.

What are the most common defects found in PCB fabrication?

Common defects include solder bridges, broken traces, and misaligned layers. These can often be avoided with proper design and quality control measures.

Can PCBs be recycled?

Yes, PCBs can be recycled. The recycling process involves recovering valuable metals like copper, gold, and silver, as well as safely disposing of hazardous materials.

What industries rely most heavily on PCBs?

Industries that rely heavily on PCBs include consumer electronics, telecommunications, automotive, aerospace, and medical devices. PCBs are essential in any industry that involves electronic devices.